Vintage Ferrari 330

Engine Block Repair

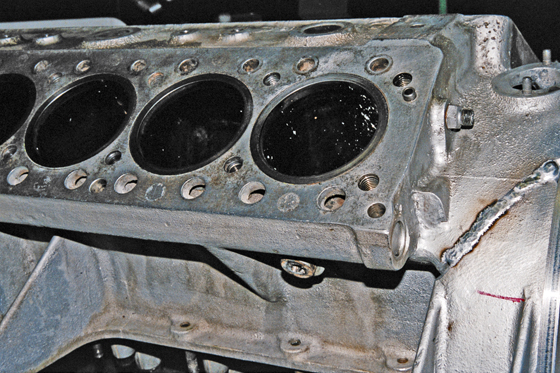

Showing left rear engine mount broken off.

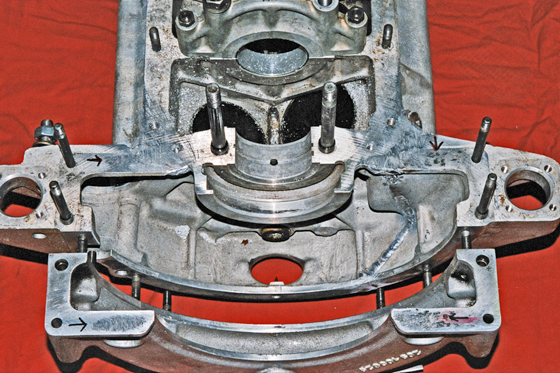

A fixture is machined in a small lathe, enabling us to bolt everything together for welding.

Fixture installed, weld joints prepared, entire rear of block bolted together and shimmed to adjust for warp age. Block will pre heated to 250 f. prior to welding.

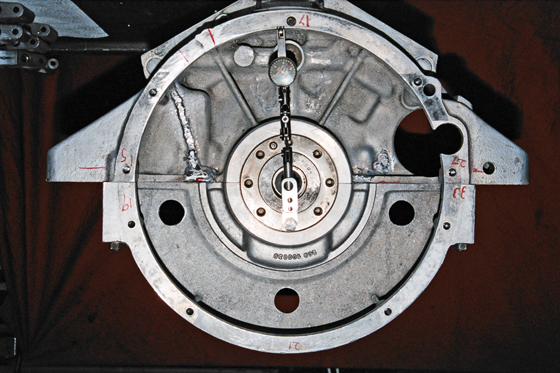

This weld will be finished to appear as though there was never a problem.

Welding completed. Evidence of chatter between the top and bottom belhousing components? This area will be machined flat. I have set everything a little high so there will be material to machine above the stock surface, leaving the finished dimensions as close to stock as possible.

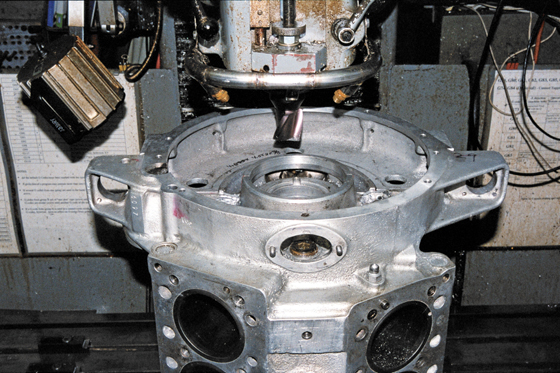

We installed the crankshaft and built a bracket to hold a dial indicator. Here we measure the transmission housing bore to determine if it is small enough to be machined to size, hopefully saving a back and forth trip between shops. This bore is about .015 inch out of round after welding and about too .030 inch small for the transmission to fit. This transmission housing bore should clean up in one pass.

There are many ways to machine the transmission housing perpendicular to the crankshaft and to correct size. We have slightly modified the end of the crankshaft and machined the block to accept a modern one piece oil seal.